Collaborating with a Chinese manufacturer is a strategic move for many businesses seeking cost-effective production solutions. However, entering the Chinese market without a robust legal framework exposes companies to significant risks. A well-drafted manufacturing agreement, customized to Chinese laws, mitigates these risks, protects your interests, and ensures a smoother partnership. Below, we dive into the critical elements to include in your manufacturing contract and the legal pitfalls to avoid.

Table of Contents

Toggle1. Intellectual Property Protection

Intellectual property (IP) theft is a pervasive issue in manufacturing agreements with Chinese partners. Companies must address this upfront to safeguard their innovations.

Key Measures to Prevent IP Misuse:

- Non-Disclosure, Non-Use, and Non-Circumvention (NNN) Agreement: Unlike standard NDAs, NNN agreements under Chinese law prevent unauthorized disclosure, misuse, and circumvention of your business.

- IP Registration: To enforce IP rights in China, trademarks, patents, and copyrights must be registered locally. Collaborate with legal experts to complete registrations before production starts.

- Breach Penalties: Include severe penalties for IP violations, such as financial damages, contract termination, or legal proceedings.

Risk of Doing It Wrong: Without an enforceable agreement, your IP can be exploited, copied, or sold to competitors, eroding your competitive edge.

2. Quality Control Measures

Poor product quality can damage your reputation and bottom line. Robust quality control clauses in your contract minimize these risks.

Provisions to Include:

- Product Specifications: Define every detail of the product, including dimensions, materials, and performance benchmarks.

- Inspection Rights: Reserve the right to inspect goods during production, using third-party services if necessary.

- Remedies for Non-Compliance: Define options such as replacement, refunds, or discounts for defective goods.

Risk of Doing It Wrong: Accepting vague quality terms may lead to subpar products, missed deadlines, and additional costs for rectification.

3. Pricing and Payment Terms

Transparent financial arrangements build trust and avoid misunderstandings. Missteps here can lead to disputes or financial loss.

Points for Negotiation:

- Pricing Structure: Clarify unit costs, minimum order quantities, and conditions for price changes due to material costs or exchange rates.

- Payment Terms: Agree on a structured timeline, typically requiring deposits before production and final payments upon shipment.

- Hidden Costs: Account for additional expenses such as packaging, taxes, and shipping fees.

Risk of Doing It Wrong: Overlooking hidden costs or payment terms can strain your budget and delay production.

4. Delivery Timelines

Timely delivery is vital for supply chain continuity. Delays can cascade into significant business disruptions.

Critical Clauses:

- Shipping Schedules: Set clear deadlines for production, inspection, and shipping.

- Penalties for Delays: Specify financial penalties for missed deadlines.

- Force Majeure: Address unforeseen events like natural disasters or political instability that could delay production.

Risk of Doing It Wrong: Without strict timelines and penalty clauses, you risk project delays and unsatisfied customers.

5. Customs, Import, and Export Compliance

Compliance with international trade laws is non-negotiable. Missteps can lead to fines, delays, or confiscation of goods.

Essential Discussions:

- Export Documentation: Ensure the manufacturer provides accurate certificates, invoices, and origin documentation.

- Import Laws: Verify compliance with your target market’s labeling, certification, and safety standards.

- Duty Allocation: Decide whether duties and taxes are the manufacturer’s or buyer’s responsibility.

Risk of Doing It Wrong: Non-compliance with customs laws can result in seized goods or legal disputes.

6. Dispute Resolution

Despite your best efforts, disagreements may arise. Proper dispute resolution mechanisms ensure faster and fairer outcomes.

Best Practices:

- Arbitration: Use arbitration through reputable centers, such as the Shanghai International Arbitration Center (SHIAC).

- Jurisdiction: Choose Chinese jurisdiction if the manufacturer’s assets are based in China.

- Governing Law: Opt for Chinese law to improve enforceability in local courts.

Risk of Doing It Wrong: A poorly defined dispute mechanism can lead to prolonged conflicts and financial losses.

7. Contract Language

The enforceability of your agreement hinges on accurate language usage.

Key Considerations:

- Draft in Chinese: Courts prioritize contracts in Chinese, reducing risks of mistranslation.

- Bilingual Contracts: If using bilingual agreements, clarify which language prevails.

Risk of Doing It Wrong: Misinterpretation of terms due to mistranslations can result in unenforceable contracts.

8. Insurance and Warranties

Insurance and warranty provisions protect against potential financial losses from defective products.

Points to Negotiate:

- Product Liability Insurance: Confirm whether the manufacturer’s insurance extends to your target markets.

- Warranty Coverage: Define warranty periods and processes for addressing defective goods.

- Shipping Insurance: Agree on coverage for goods in transit.

Risk of Doing It Wrong: Failing to secure insurance exposes your business to financial liability.

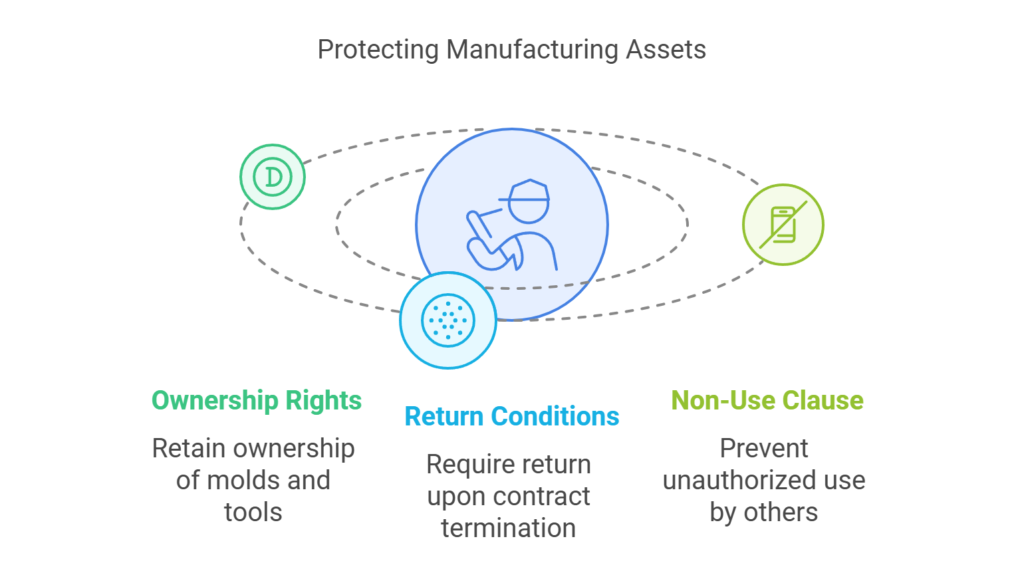

9. Mold and Tooling Ownership

Molds and tools are often significant investments in manufacturing. Define ownership and usage rights to protect these assets.

Must-Have Clauses:

- Ownership Rights: Retain ownership of molds and tools.

- Return Conditions: Require the return of molds upon contract termination.

- Non-Use Clause: Prevent unauthorized use of your molds for other clients.

Risk of Doing It Wrong: Allowing manufacturers to use your molds without restrictions can lead to unauthorized production.

10. Exclusivity and Non-Compete Clauses

Protect your market position by defining exclusivity and competition restrictions.

Suggested Inclusions:

- Exclusivity: Restrict manufacturers from working with competitors during the agreement period.

- Non-Compete Clauses: Prohibit manufacturers from entering markets that directly compete with your business.

Risk of Doing It Wrong: Poorly written clauses may fail to protect your competitive advantage under Chinese law.

11. Liability and Indemnification

Allocate risks and responsibilities clearly to avoid disputes.

Important Provisions:

- Manufacturer Liability: Hold manufacturers accountable for deviations from agreed specifications.

- Indemnification: Require manufacturers to cover losses from defective products or regulatory violations.

Risk of Doing It Wrong: Undefined liability can result in financial and reputational damage.

12. Termination Conditions

Clearly define how and when the agreement can be terminated to avoid protracted disputes.

Key Points:

- Termination Grounds: Include reasons such as insolvency or quality issues.

- Notice Periods: Agree on a reasonable notice period.

- Post-Termination Obligations: Address unresolved payments and return of proprietary equipment.

Risk of Doing It Wrong: Ambiguous termination clauses can lead to costly legal disputes.

Conclusion

Collaborating with a Chinese manufacturer offers substantial opportunities, but it also comes with legal and operational risks. A comprehensive manufacturing agreement, tailored to Chinese laws, is your best tool for minimizing these risks and ensuring a successful partnership. From intellectual property protection to dispute resolution mechanisms, covering every detail upfront is essential.

Failing to address these key points could expose your business to financial loss, damaged reputation, and legal entanglements. By partnering with experienced legal professionals and conducting thorough due diligence, you can safeguard your interests and build a productive, long-term relationship with your Chinese manufacturing partner.

FAQ: Legal Risks and Best Practices for Manufacturing Agreements in China

1. Why is an NNN agreement important for working with Chinese manufacturers?

An NNN (Non-Disclosure, Non-Use, and Non-Circumvention) agreement is specifically designed for Chinese law and is much more robust than standard NDAs. It ensures:

- Confidentiality: Protecting your proprietary information from being shared with third parties.

- Proper Use: Restricting the manufacturer from using your IP outside of the agreed terms.

- Non-Circumvention: Preventing the manufacturer from bypassing you to work directly with your clients or competitors.

2. What happens if I don’t register my intellectual property in China?

IP rights, such as trademarks and patents, must be registered in China to be legally enforceable. If you neglect registration:

- Your IP could be copied or used without permission.

- Competitors could register your IP in China and block your access to the market.

- Legal actions to protect your IP would be much more difficult and costly.

3. How can I ensure product quality meets my standards?

To safeguard quality:

- Include detailed product specifications in the contract.

- Reserve the right to conduct inspections during production, either directly or through a third-party quality control service.

- Specify penalties for non-compliance, such as refunds, replacements, or discounts.

4. How do I protect myself financially when working with a manufacturer?

Financial security comes from:

- Agreeing on transparent pricing structures, including handling of raw material price changes and exchange rate fluctuations.

- Using structured payment terms, such as deposits before production and final payments after inspection.

- Clarifying all additional costs, such as packaging and taxes, to avoid hidden charges.

5. What are the risks of vague delivery timelines?

Vague timelines can lead to:

- Production delays, disrupting your supply chain.

- Missed customer deadlines, affecting your reputation.

- Financial loss due to late deliveries.

To prevent this, specify production and shipping schedules, include penalties for delays, and address unforeseen events through force majeure clauses.

6. What documentation should I require for customs and compliance?

Ensure the manufacturer provides:

- Export documentation, such as certificates of origin and invoices.

- Compliance with import regulations in your target market, including product labeling and certifications.

- Agreements on who will bear the costs of duties and taxes.

7. What is the best way to resolve disputes with a Chinese manufacturer?

Arbitration is often the best choice for international contracts. To enhance enforceability:

- Choose a reputable arbitration center, like the Shanghai International Arbitration Center (SHIAC).

- Specify Chinese jurisdiction if the manufacturer’s assets are in China.

- Use Chinese law as the governing law for your contract.

8. Why should I draft the contract in Chinese?

Chinese courts prioritize contracts written in Chinese. A bilingual contract can also work, but the Chinese version should explicitly prevail in case of discrepancies to avoid interpretation issues.

9. How do I protect my investment in molds and tooling?

To safeguard your proprietary equipment:

- Specify in the contract that you retain ownership of molds and tools.

- Prohibit the manufacturer from using your molds for other clients.

- Require the return of molds upon termination of the agreement.

10. Can I restrict the manufacturer from working with my competitors?

Yes, by including exclusivity and non-compete clauses:

- Exclusivity: Prevents the manufacturer from producing similar products for your competitors.

- Non-Compete: Prohibits the manufacturer from entering markets that compete with your business.

Ensure these clauses comply with Chinese law to be enforceable.

11. What liabilities should the manufacturer cover?

The manufacturer should:

- Be held liable for defects caused by deviations from agreed specifications.

- Indemnify you for any losses arising from defective products or regulatory violations in your target market.

12. What should I include in termination clauses?

Termination clauses should define:

- Grounds for termination, such as breach of contract or quality issues.

- Notice periods for termination.

- Post-termination obligations, like returning molds, settling payments, or completing outstanding orders.

13. What insurance should I require the manufacturer to have?

To mitigate risks:

- Confirm the manufacturer has product liability insurance that covers your target market.

- Agree on warranty terms for addressing defective products.

- Decide who will arrange shipping insurance for goods in transit.

14. What happens if I don’t address these legal risks in my contract?

Neglecting these key points can lead to:

- Loss of intellectual property.

- Financial disputes or unexpected costs.

- Quality issues damaging your reputation.

- Legal disputes that are costly and time-consuming to resolve.

15. How can I ensure my manufacturing agreement is enforceable under Chinese law?

Work with legal experts familiar with Chinese regulations. Draft a comprehensive contract in Chinese or bilingual format, and ensure all clauses align with Chinese laws for maximum enforceability.